Camillo Cardelli completed PhD from Pisa University in 2000. Until 2003 he was a contract researcher at the National Council of Research of Italy for studies about halogen-free, flame retardant polymeric materials for cables. In 2008 Cardelli pursued MBA from Scuola Superiore Sant’Anna di Pisa where he studied “Management of Innovation”. He is an expert in HFFR Cable Compounding, having published more than 20 papers in international Journals & Magazines along with Speeches, posters, papers at international Exhibitions and Congresses.

One of our most important customers for ACP was able to further increase, their already very high, MDH content, by using VISCOSPEED. Having similar processability, the new panel was more cost-efficient and achieved better flame retardant properties with PCS<9 MJ/kg.

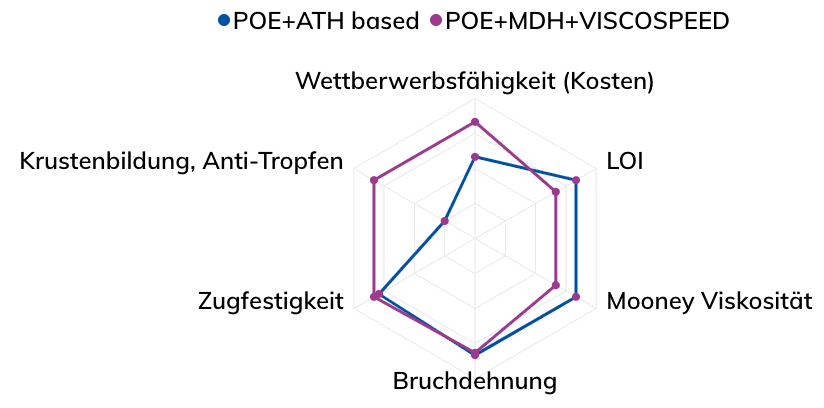

Thanks to extensive study of VISCOSPEED in different cable compounds, INNOSPEC found a way to completely avoid aluminium hydroxide (ATH) in CPR compliant sheathing compounds. With the suitable polymer components and the optimal dispersion of natural magnesium hydroxide (MDH) by VISCOSPEED, mechanical and flame retardant properties were suited for EN 50399 regulation. The main results of these studies were published in the October 2020 issue of the Compounding World magazine. The results of our study were published in Compounding World in October 2020.

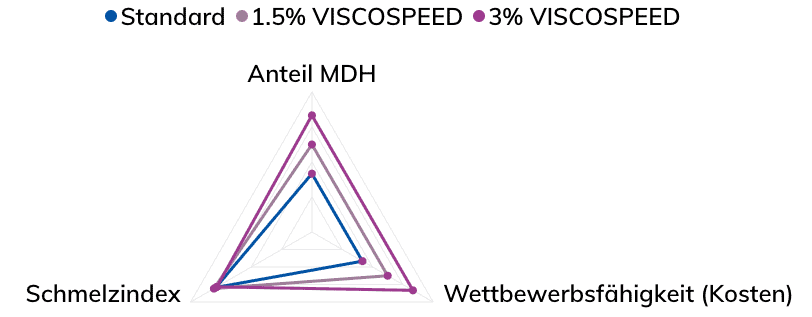

One of our customers producing concentrates for TPO roofing membranes, is able to considerably increase the MDH content and at the same time maintain processability. VISCOSPEED helped to achieve an increase of 12 % towards 82 % MDH-content. The increased filler content had a big impact to lower compound cost and additionally optimized flame retardant properties for the end- user.

"VISCOSPEED is a versatile additive, which has achieved positive results in all my studies. That is why it is now a permanent part of my development work for new formulations for halogen-free flame retardant compounds. In most cases, VISCOSPEED brings the decisive advantage.

VISCOSPEED is really a perfect additive for my development."

To broaden our portfolio and allow our customers to tackle even more complex requirements of their formulations and final goods, we developed two additional VISCOSPEED grades.

First, VISCOSPEED High Temperature HT, it combines polarity and a high drop melting point, allowing dosage at elevated temperatures, where other materials already tend to soften and block.

And secondly, VISCOSPEED High Polarity HP assures a higher affinity to the inorganic filler and a softer character of the material.

All three grades VISCOSPEED, VISCOSPEED HP and VISCOSPEED HT are well suited for your compounding of inorganic fillers or pigments.

HFFR Cables:

ACP:

TPO Membranes:

Semicon:

HFFR Cables:

ACP:

TPO Membranes:

Semicon:

HFFR Cables:

ACP:

TPO Membranes:

Semicon:

Ethylene is our base. We polymerize at high pressure, i.e. at 2,000 bar. This is how we produce waxes and other specialty products such as diesel additives for freezing temperatures.

Since 2004, Innospec Leuna has been part of the global Innospec Group, which focuses on chemical additives for various applications. In Leuna we employ 110 people and generate about €50 millions in sales. Our customers benefit from our flexibility, high quality standards, good application-related advice and competitive conditions.

Please do not hesitate to contact us. We will get back to you promptly by e-mail. Or test our product yourself: We will send you a sample of Viscospeed within 10 working days.

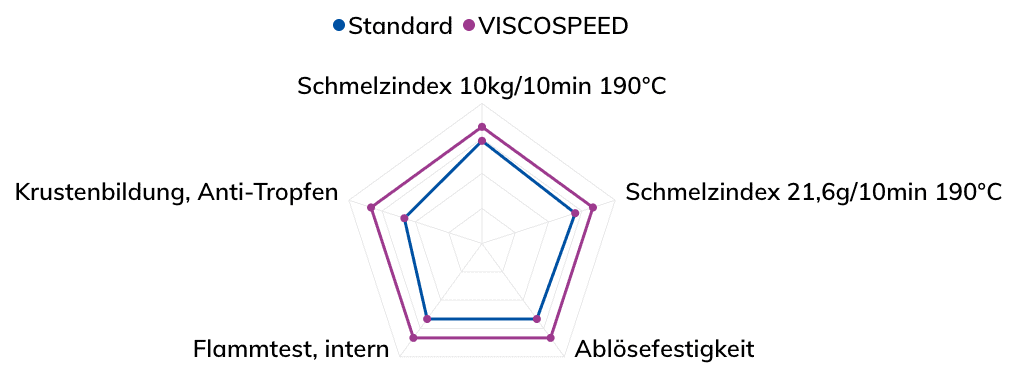

VISCOSPEED is a special polar polymer with waxy-like properties, designed to optimize the processing of halogen-free flame retardant (HFFR) compounds.

In opposite to other processing aids VISCOSPEED does not cause a decrease in flame retardancy. In fact it is able to optimize flame retardant performance. Moreover, VISCOSPEED acts as internal lubricant and yields a more homogeneous melt.

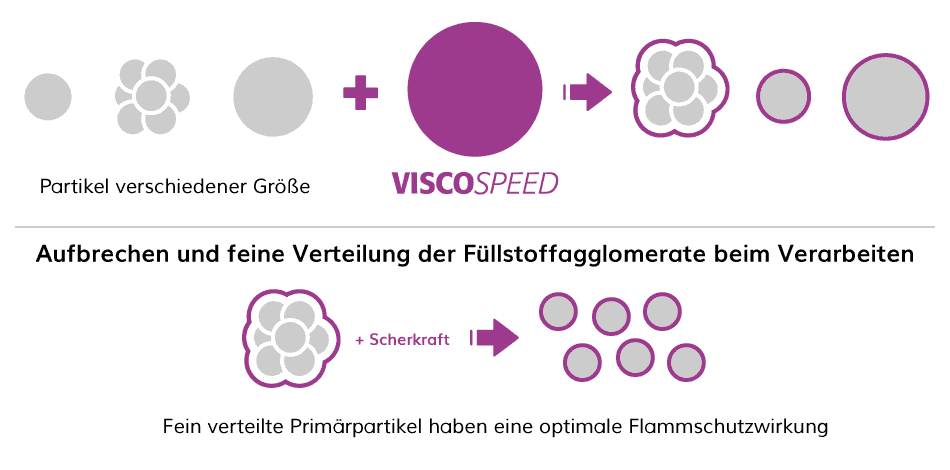

VISCOSPEED is able to destroy flame retardant filler aggregates into primary particles and enables an efficient dispersion of the filler, causing a more efficient flame retardancy. Furthermore, due to its special composition, VISCOSPEED is able to interact with the inorganic filler to improve char formation and ultimately the anti-dripping behaviour. This is especially important for non-polar base polymers.

Depending on the application and special formulation, VISCOSPEED is used in different concentrations from 0.5 to 3 percent. Get in touch with us to get a recommendation for your formulation.

VISCOSPEED is available as dust-free powder of a mean particle size of 0.5 mm or granules (mean particle size of 4 mm).

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information